Polyurethane aluminum anti-corrosion paint for steel, metal, or concrete. Can be applied at low temperatures (-18°C) and high humidity (up to 99%)— practically year-round, regardless of weather conditions. For anti-corrosion protection and painting of bridges, steel structures, roofs, steel pipes, etc.

- Wroclaw,

- Katowice,

- Warsaw,

- Gdansk,

- +48 717 026 346

Anti-corrosion protection

Anti-corrosion protection

Products in this category provide protection against corrosion, a process of material degradation caused by reaction with the surrounding environment. Protection using specialized agents maintains the durability and reliability of metal components and extends their service life. Anti-corrosion protection is essential for all types of metal structures, components, and machinery.

Call us - we will help you choose the anti-corrosion system: +48 717 026 346

Thanks to their properties, anti-corrosion agents provide ideal protection against the harmful effects of corrosion and are often used in industry.

Anti-corrosion paint guarantees:

- resistance to weather conditions and chemical stress,

- long-term durability - up to 25 years of durability

We color our paints according to the RAL palette .

Anti-corrosion protection for your home

The use of anti-corrosion paints isn't limited to industrial structures. We also offer paints that can be used to protect metal elements in your home or garden. Anti-corrosion paints are also perfect for protecting balcony and patio railings, as well as metal fences and gates. Specialized fence paints are available in a wide range of colors and finishes, allowing you to customize the paint to your preferences and achieve the desired anti-corrosion and visual effect.

Anti-corrosion paint for demanding environments

Are you looking for paint that you can apply to metal parts in difficult conditions?

Check out our offer of anti-corrosion paints with corrosion classes C4 and C5 .

The C4 corrosivity class applies primarily to coastal and industrial environments, while the C5 class is used when metal structures are exposed to gases present in the air, including carbon dioxide, hydrogen sulphide, and sulfuric acid vapors.

Products operating in these corrosivity classes guarantee high protection of metal surfaces and are worth choosing if you want adequate anti-corrosion protection, even in the most difficult environmental conditions.

Our anti-corrosion paint systems for steel and non-ferrous metals are widely used and create a durable coating, providing the highest level of corrosion protection in corrosivity categories from C-1 to CX.

Our offer includes:

Anti-corrosion paints:

- RAYSTON SILVER 1K: Provides effective and durable protection for steel and concrete surfaces. The product is resistant to weathering and UV radiation. It can be applied in sub-zero temperatures, down to -18°C! It has anti-corrosion and barrier properties. It can also be used as an adhesive and protective layer.

- Noxyde/Peganox : Provides excellent anti-corrosion protection for structures such as bridges, metal roofs, metal facades, and steel structures. These paints withstand highly corrosive environments, including industrial and marine environments (C5-I and C5-M classes). They are ideal for use in industrial environments. Importantly, they do not require sandblasting and can be applied directly to rust.

- Heat-resistant paints and varnishes : They can be applied to new, clean or sandblasted steel surfaces or to pre-treated surfaces, e.g. exhaust pipes, boiler room equipment, grates, grills, fireplaces, radiators, etc. They provide anti-corrosion and heat-resistant protection.

- High-zinc paints : They have a high zinc dust content and provide excellent anti-corrosion protection.

Primers, enamels and primer-enamels

- Epoxy paints : Designed for use as a topcoat in interior anti-corrosion paint systems. They can also be used on mineral substrates, such as masonry.

- Polyurethane paints : They are characterized by excellent resistance to moisture and chemicals. They are UV-resistant. They are primarily used for painting steel, wood, and concrete surfaces. They are flexible and exceptionally abrasion-resistant.

- Polyvinyl : Designed mainly for painting steel and galvanized steel structures, for anti-corrosion protection, mainly for steel roofs and metal facades, gates, grilles, fences, lanterns, balustrades, various useful and decorative objects made of forged steel, machine housings, devices, etc.

- Alkyd : Designed for outdoor and indoor areas with moderately corrosive atmospheres (industrial areas, steel structures, containers, pipes, workshops, laundries, basements), metal and steel structures and halls, metal elements, metal furniture, doors, door frames, metal and concrete fences, paneling, metal fittings, industrial trolleys and facilities, machine housings, agricultural and mining machines.

- Acrylic : characterized by excellent adhesion to steel, galvanized steel (including fresh galvanized steel), aluminum, and copper. For undemanding, economical work.

- Chlorinated rubber primers : Designed for interior and exterior painting, except in chemically aggressive environments. They can be used to protect:

- steel and cast iron surfaces for corrosion protection and decorative purposes, including machinery, equipment, industrial and construction structures, barriers, poles, fences, streetlights, etc.

Anti-corrosion sprays:

Ideal for application directly to substrates such as aluminum, brass, bronze, and chrome, they provide a protective coating. Anti-corrosion sprays are quick-drying and non-yellowing.

Sprays we recommend:

- Colorless topcoat spray HARD HAT RO2500 .

- Anti-corrosive spray primers for painting small surfaces or corrections, from the HARD HAT .

We will help you choose anti-corrosion paints, call: +48 717 026 346

Product offer

Water-based anti-corrosion coating for application by roller or brush. No priming required.

A fish oil-based anti-corrosion primer. It is lead- and chromate-free, making it virtually odorless. No topcoat is required for corrosion protection.

Heat-resistant paint that protects against heat up to 750°C with dry heat and short-term exposure. Resistant to continuous temperatures up to 600°C. Based on silicone-modified alkyd resin.

A fast-drying, cold galvanizing product. For use on new or cleaned steel surfaces. Based on polyhydroxyether resin.

Polyvinyl paint with a high zinc content. Designed for priming and filling gaps in zinc coatings.

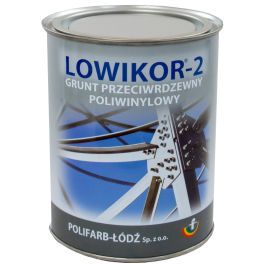

A product for professional protection of steel and galvanized steel structures. It is PZH-approved, allowing it to be used on steel structures in industrial and construction applications inside buildings.

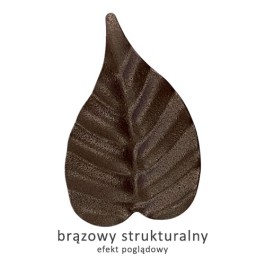

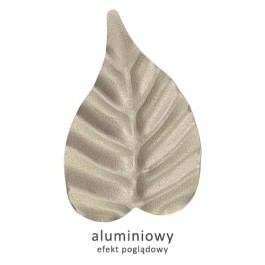

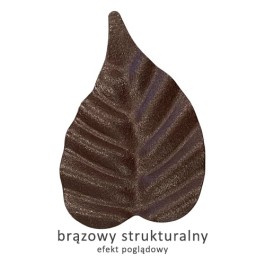

A decorative primer with a fine-grained texture. Designed for protective and decorative painting of metal surfaces without prior priming.

A highly decorative primer for the protective and decorative painting of metal surfaces. Highly opaque, hard, and scratch-resistant.

An anti-corrosion coating with a 90% zinc content in the dry film. Provides cathodic protection. For use on new or very clean steel surfaces.

A single-component anti-rust primer with active anti-corrosion pigments. Combined with polyvinyl paints, it provides excellent anti-corrosion protection. For steel, cast iron, and aluminum.

- NOTE: THIS IS A WATER-BASED PRODUCT. Select temperature-controlled shipping to receive your product on the promised date, regardless of weather conditions. Standard shipping may be delayed due to temperatures below 5°C encountered along the delivery route.

A water-based product for decorating metal objects. It's perfect for decorating fences, artistic blacksmithing, and metalwork.

- NOTE: THIS IS A WATER-BASED PRODUCT. Select temperature-controlled shipping to receive your product on the promised date, regardless of weather conditions. Standard shipping may be delayed due to temperatures below 5°C encountered along the delivery route.

Anti-corrosion primer for metals. Air-dries quickly. Available in red oxide and gray.

Polyvinyl paint for painting fences, artistic blacksmithing, and historic renovations. It creates a matte, smooth coating. Recommended for use with Lowikor-2 primer.

Anti-corrosion and decorative polyvinyl paint for steel and cast iron structures. Creates a fine-grained coating.

For removing rust and protecting surfaces against corrosion. Has rust-removing, barrier, and penetrating properties.

Anti-corrosion enamel for use on steel and cast iron structures, non-ferrous metals as well as concrete, wooden and plastered surfaces to protect against the harmful effects of atmospheric factors.

Provides anti-corrosion, cathodic protection for steel. Suitable for application to small surfaces, filling gaps, and for repair work. Leaves an aesthetically pleasing finish.

This spray leaves a coating with the sparkling look of stainless steel. It provides thermal protection up to 100°C. The coating is mechanically, chemically, and UV resistant.

Anti-corrosion spray primer for small surfaces or touch-ups. Suitable for use on lightly corroded steel. Lead- and chromate-free.

A primer for small surfaces, such as for filling gaps or finishing work. It can also be used as a finishing coat. Suitable for mildly corrosive environments.

A reinforcing primer for sealing and stabilizing substrates. For new and old surfaces.

A semi-matte primer that can be applied independently with a roller or brush. Available in a variety of colors.

A quick-drying industrial primer/enamel. Available in a variety of colors, it requires no priming and contains anti-corrosive pigments.

A quick-drying metallic galvanized coating that provides cathodic protection and a metallic finish. Contains zinc and aluminum pigment. Highly resistant and easy to apply.

Alkyd topcoat available in several finishes. Suitable for interior and exterior use. Excellent for creating topcoats on wood and concrete, among other surfaces.

Alkyd primer recommended for painting large surfaces, such as containers. Does not bleed at edges. Excellent adhesion.

Industrial-grade primer. Protects against rust in environments up to corrosivity class C3. Many colors to choose from.

Single-component primer/finish that protects against rust in environments up to corrosive class C3. Available in a variety of colors.

Industrial polyvinyl primer for indoor and outdoor use on steel structures, sheet metal roofs, etc.

Epoxy primer for steel. Protects against corrosion and has high chemical resistance.

Industrial epoxy primer. Protects against corrosion and has excellent adhesion to metals and galvanized substrates.

Industrial epoxy primer. Does not require priming and does not run on vertical surfaces. Suitable for steel, mineral, and galvanized surfaces.

High-gloss epoxy enamel. For use as a topcoat in interior anti-corrosion systems. Highly mechanically and chemically resistant.

High-gloss industrial polyurethane enamel. Suitable for spray application. Highly chemically and mechanically resistant.

Industrial enamel for use as a topcoat in anti-corrosion systems. It dries quickly and is highly resistant to chemicals and weather conditions.

Primer for steel and cast iron surfaces. Can be used for temporary anti-corrosion protection, e.g., during storage.

A primer based on alkyd resin with silicone that provides anti-corrosion protection and high temperature resistance.

Heat-resistant anti-corrosion paint for steel and aluminum surfaces. Resistant to high temperatures, up to 500°C.

- NOTE: THIS IS A WATER-BASED PRODUCT. Select temperature-controlled shipping to receive your product on the promised date, regardless of weather conditions. Standard shipping may be delayed due to temperatures below 5°C encountered along the delivery route.

A resin-based heat-resistant enamel topcoat that provides high temperature resistance up to 200°C.

A topcoat for painting containers. It has excellent weather resistance, dries quickly, and doesn't streak.

A primer for epoxy, acrylic, and polyurethane topcoats. Durable in changing weather conditions, continuous contact with water, and industrial environments. Provides anti-corrosion protection and excellent adhesion.

- NOTE: THIS IS A WATER-BASED PRODUCT. Select temperature-controlled shipping to receive your product on the promised date, regardless of weather conditions. Standard shipping may be delayed due to temperatures below 5°C encountered along the delivery route.

Anti-corrosion primer for use under water-based coatings. Suitable for both indoor and outdoor use.

- NOTE: THIS IS A WATER-BASED PRODUCT. Select temperature-controlled shipping to receive your product on the promised date, regardless of weather conditions. Standard shipping may be delayed due to temperatures below 5°C encountered along the delivery route.

Water-based, single-component rust neutralizer. Reacts with rust and creates a stable protective layer. For use under solvent-based or water-based paints and resins.

A water-based primer that facilitates paint adhesion to difficult substrates.

water-based, solvent-based, and solvent-free coatings

A primer that protects surfaces from rust in corrosivity classes C3 to CX. Can be applied even over rust residue. Contains aluminum pigments.

An epoxy resin primer for industrial applications. Quick-drying and high-build, it provides anti-corrosion protection for metal surfaces.

A concentrated agent for degreasing surfaces before painting. Recommended primarily for use before painting with anti-corrosion products.

- NOTE: THIS IS A WATER-BASED PRODUCT. Select temperature-controlled shipping to receive your product on the promised date, regardless of weather conditions. Standard shipping may be delayed due to temperatures below 5°C encountered along the delivery route.

- Product

- Preparation of the substrate

For cleaning concrete, roof tiles, and metal before applying paint. Requires rinsing with water.

What is corrosion?

keyboard_arrow_down keyboard_arrow_upCorrosion is the process of material destruction due to external factors. Destructive factors include proximity to seawater or freshwater, the presence of chlorides or sulfur compounds in the environment, or simply atmospheric conditions. The product of the corrosion process is rust, a coating that forms on the metal.

Corrosivity Categories - What are They?

keyboard_arrow_down keyboard_arrow_upCorrosivity categories are used to define the degree of corrosiveness. According to the PN EN ISO 12944-2 standard, this corrosiveness is classified into six levels for the atmosphere and three levels for water and soil. To properly select a painting system, it is necessary to determine the conditions in which the structure will operate, and therefore determine the environmental corrosivity category. These categories are as follows: C1 - very low degree of corrosive aggressiveness, internal structure in a heated room with a clean atmosphere (example: shops, offices, school) C2 - low degree of corrosive aggressiveness, external structure in a rural environment or internal structure in an unheated room where condensation may occur (example: warehouses, sports halls) C3 - medium degree of corrosive aggressiveness, external urban or industrial environment, internal environment with high humidity and air pollution (example: breweries, laundries, dairies) C4 - high degree of corrosive aggressiveness, external industrial environment, coastal areas with medium salinity, internal environment such as chemical plants, swimming pools, repair shipyards C5-I - very high degree of corrosive aggressiveness (industrial) - external environment with high humidity and aggressive atmosphere, and internal environment with almost constant condensation and high pollution C5-M - very high degree of corrosive aggressiveness (coastal) - areas coastal, distant from the shore After appropriate selection of the environmental corrosivity class and determining the minimum required durability of the painting, the appropriate thickness of the paint coating can be selected and the theoretical yield of the product can be determined.

What are good paints for metal fences?

keyboard_arrow_down keyboard_arrow_upTwo-component polyurethane paints are the most durable. They provide excellent protection against corrosion and UV radiation. Application of these paints is more difficult due to the need to combine the two components and mix them thoroughly. These products should typically be applied at temperatures above 10°C. One such product is the Telpur S210 primer-finish . It is available in 2, 2, and 10 kg packages in RAL colors. If a small amount of paint is needed, the Lowigraf-Pur two-component primer-finish . It is available in 0.88 l and 2.75 l packages in a limited color range. In highly corrosive environments (e.g., if the fence is located next to a busy road or a sidewalk that is salted in winter), we recommend applying an epoxy primer before applying the polyurethane paint. This can be FEG-C or Telpox P 100 . If we want a simple and quick application, we can choose single-component products, for example Stal-Kor rust primer or Lowigraf polyvinyl paints.

Does the rust remover need to be washed off?

keyboard_arrow_down keyboard_arrow_upThere's no need to wash off the rust remover. Depending on the product chosen, you simply need to wait a specific time before applying subsequent coats: If using Top-Kor , wait 12 hours. Top-Kor can only be repainted with solvent-based paints. If using Neodur Metalforce , wait 24 hours. Neodur Metalfroce can be repainted with both solvent-based and water-based paints. When applied to rusted iron surfaces, the rust remover will create a very stable, graphite-gray/black layer that will resist further oxidation. When applied to smooth, non-rusted steel, it will create a colorless varnish coat with good adhesion to the substrate, blocking out moisture and oxygen from the air and temporarily protecting the substrate from corrosion.

How to prepare galvanized steel for painting?

keyboard_arrow_down keyboard_arrow_upNot all paints can be applied to a freshly galvanized surface. Galvanized surfaces should be seasoned for approximately six months. If repainting is necessary, the structure should be washed with an ammonia solution before painting.

How to prepare a structure for painting?

keyboard_arrow_down keyboard_arrow_upTo properly prepare the structure for painting, first of all, the surface must be mechanically cleaned (removing old, flaking coatings and loose rust) and degreased. Emulsol RN-1 surface degreaser can be used for this purpose. This highly efficient product, which, when prepared at a 2-3% solution (0.5 liters in approximately 16-25 liters of water), is sufficient to clean 20 to 50 m², depending on the degree of contamination. If the surface has rust that cannot be removed mechanically, it is best to use a rust remover. If the surface will be repainted with solvent-based paints, Top-Kor , which is applied by brush, roller, or spray. One liter of the product is sufficient to protect approximately 10 m². Wait 12 hours before applying subsequent coats. Another product for removing rust from surfaces is Neodur Metalforce , which can be used under both solvent-based and water-based paints. After applying the product, wait 24 hours before applying subsequent coats. Depending on the topcoat used and the substrate, it may be necessary to prime the surface with an anti-corrosion primer.

How long does it take for metal paint to dry?

keyboard_arrow_down keyboard_arrow_upDrying times vary depending on the product and are individual. Substrate and ambient temperature, as well as air humidity, are key factors influencing drying time. For most single-component products, a general rule can be applied: solvent-based products dry faster than water-based ones. This is because the solvent is more volatile and evaporates from the surface faster than water. Example drying times for single-component paints: Lowicin (solvent-based polyvinyl paint for galvanized roofs) - 2-3 hours; eko-Lowicyn (water-based acrylic paint for galvanized roofs) - 12 hours; Telkyd S 200 TM (solvent-based polyvinyl primer-finish) - dust-free after just 20 minutes. Two-component products (epoxies or polyurethanes) typically have longer drying times because, in addition to physical drying, a chemical reaction occurs between the base and the paint hardener. Drying times for two-component paints (colloquially speaking, when they stop sticking) are 0.5-3 hours, depending on the product. However, it's important to remember that this doesn't mean the structure can be transported or repainted after that time. Example drying times for two-component paints: Telpur T 300 matt - dry to touch 0.5-1 hour - repainting after 24 hours Telpox T 300 - dry to touch 1-4 hours - repainting after 24 hours Telpox P 100 - dry to touch 0.5-2 hours - repainting after 24 hours There are cases where a long drying time is an advantage. For example, when spray painting with high-gloss paints, a longer drying time will work to our advantage. During spray painting, so-called paint mist is created, which, as it settles, should blend into the paint layer already applied to the substrate. If the paint dries too quickly, the falling particles won't be able to bond with it, creating an unsightly "dust"—tiny dots. This is why Telpur T 300 (gloss version) has a longer drying time. If a short drying time is important, consider products that allow for a wet-on-wet second coat, such as Telkyd S 200 TM or Telpur S 210 .

Proven products

We offer products with high durability and technical parameters, ensuring long-lasting results.

Help in choosing

Wondering which products will best suit your needs? Call us – we'll advise you and choose the right solution.

Contractor support

Need help with construction work? Let us know, and we'll recommend trusted contractors.

Stationary points

Want to pick up your products in person? Or perhaps you'd prefer to chat face-to-face? Visit our branches in Warsaw, Wrocław, Katowice, or Gdańsk.