Solvent-based epoxy primer for epoxy paints and polyurethane resins. For use on floors and walls, where high mechanical and chemical resistance is required.

- Wroclaw,

- Katowice,

- Warsaw,

- Gdansk,

- +48 717 026 346

Resin on the floor

Resin floors are becoming increasingly popular among those seeking durable, aesthetic, and functional interior solutions. Resin floors offer a wide range of advantages, making them ideal for both domestic and commercial spaces, including industrial applications.

What is resin on the floor?

Resin flooring is a finishing material used on various surfaces, made from synthetic polymers such as epoxies , polyurethanes , and polyureas . It is characterized by high resistance to mechanical damage, moisture, and chemicals, making it an ideal choice for demanding applications.

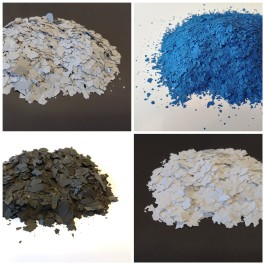

The resin creates a uniform, smooth surface that can be finished in various finishes, from matte to glossy. Thanks to the ability to dye and add decorative elements such as decorative flakes liquid granite imitation , resin flooring allows for unique visual effects.

Why is it worth using resin on the floor?

Resin floors offer many benefits that make them an attractive solution for a variety of interiors:

- Durability: The resin is extremely resistant to abrasion, impact and chemical agents.

- Aesthetics: The smooth surface and variety of finishes allow you to match the floor to any interior style.

- Uniform surface: The lack of joints and crevices makes it easier to keep clean and gives the interior a modern character.

- Moisture resistance: Resin is ideal for use in rooms exposed to moisture, such as bathrooms and kitchens.

- Possibility of personalization: The ability to create patterns, change colors and special effects provides enormous scope for creating individual flooring designs.

Where can resin flooring be used?

Resin floors are used in a wide variety of applications, both in residential and industrial settings. Here are a few examples:

- In homes: in living rooms, kitchens, bathrooms, garages and basements.

- In commercial facilities: offices, shops, shopping malls.

- In industrial facilities: warehouses, workshops, laboratories.

- In public spaces: schools, hospitals, gyms.

What types of flooring resins are available?

Resin floors can be made from a variety of materials, each with its own specific characteristics and applications.

Epoxy resin

Epoxy is one of the most popular options, known for its exceptional durability and chemical resistance. It's ideal for industrial applications and areas where floors are subject to heavy use. Epoxy floors are designed for heavy loads, so they can withstand the impact of forklifts, trucks, and other heavy equipment.

Polyurethane resin

Polyurethanes are characterized by flexibility and UV resistance, making them an excellent choice for sunny locations and outdoor surfaces. Their structure is more flexible than hard epoxies. They can often be used interchangeably, but in some cases, polyurethanes are the first choice due to the more flexible nature of the surface they create.

Polyurea resin

Polyureas cure quickly, which is their greatest advantage in situations where project completion time is crucial. They are resistant to changing weather conditions. An additional advantage of this type of resin is the low temperature at which the curing process takes place. Both epoxies and polyurethanes typically require temperatures around 10°C or higher for proper curing, while polyureas, also known as polyaspartates, require temperatures of +5°C or even lower! This makes it possible to work in challenging conditions, such as the low temperatures experienced in autumn, winter, or early spring.

Advantages of resin on the floor

- Durability: Resin floors are resistant to mechanical and chemical damage. Properly applied, resin floors can withstand heavy loads, such as heavy use by cars, forklifts, and heavy pedestrian traffic, such as in shopping malls.

- Easy to clean: The smooth, seamless surface is easy to keep clean. Maintaining a resin floor often requires only a soft mop, mild detergent, and warm water.

- Aesthetics: A wide selection of colors and decorative effects. Most resin floors are fully customizable, so you can easily create the floor of your dreams!

- Moisture resistance: A great option for bathrooms and kitchens. Resin-based materials are ideal for protecting concrete and indoor tiles, so they can be used in areas such as showers and under sinks. These areas are particularly susceptible to moisture, which doesn't prevent resin floors from being used. Resin floors also protect outdoor areas such as balconies, terraces, and even roofs from moisture.

- Versatile Applications: Suitable for both residential and commercial/industrial spaces, the advantages described above clearly demonstrate that resin flooring can be used in a wide range of applications, depending on your needs.

How to prepare the floor for resin?

Substrate preparation is a crucial step in creating a resin floor. This step will determine the floor's appearance, as well as the adhesion of the resin coating. Here are the steps to take:

- Substrate Assessment: Ensure the surface is dry, clean, and free from damage. Repairs may be necessary. Of course, before applying the resin, the floor must be vacuumed to remove small dust particles and other dirt, which are not necessarily visible to the naked eye and whose presence significantly affects the adhesion of the entire resin system.

- Surface leveling: The substrate must be even, free from cracks and voids. Any unevenness should be filled and the floor leveled using cement mortar or resin filler, such as epoxy.

- Priming: During the priming stage, a primer, also a resin, is applied to create adequate adhesion for the actual flooring protection layer. There are various types of resin primers, from quick-drying polyurea-based ones to those designed for use on both dry and damp concrete. A properly primed concrete substrate should be uniformly glossy, with no dull spots visible when held up to light.

- Applying resin layers: Successive layers of resin are applied to the previously prepared surface, according to the chosen flooring system. These can be resin materials in a specific color, self-leveling polyurethanes or epoxies with a mirror effect, or the aforementioned quick-drying polyurea resins.

Care and maintenance of resin floors

Resin floors are easy to clean , but they require proper care to maintain their appearance and performance for years to come. Here are some top tips:

- Regularly remove dirt with a soft cloth or mop.

- The use of aggressive chemicals that may damage the surface is prohibited. Unless the manufacturer recommends otherwise, but it's always worth checking the technical data sheet.

- In case of scratches or damage, consult a professional for repair.

Product offer

Epoxy resin for use as a primer or structural resin. A solvent-free product for priming walls and floors and creating epoxy screeds.

A solvent-free, epoxy primer that strengthens cementitious substrates. For interior and exterior use.

Solvent-free epoxy primer intended for use on concrete with no or improperly installed damp proofing.

A systemic primer for use under Neodur Fast Track polyurea/polyaspartic flooring resin. It can be applied at low temperatures, down to -10°C. It allows for the application of the surface within 3 hours of applying the primer (at +25°C).

A hybrid primer (polyurethane-polyurea) that allows for topcoat application in just 3 hours. It provides high mechanical and chemical resistance.

Troken Floor EPS is a self-leveling, two-component epoxy screed that also creates a scratch coat. This solvent-free product features low VOC emissions and high mechanical resistance, characterized by a gray tint. It is ideal as part of a resin flooring system in residential, industrial, and public spaces.

- NOTE: THIS IS A WATER-BASED PRODUCT. Select temperature-controlled shipping to receive your product on the promised date, regardless of weather conditions. Standard shipping may be delayed due to temperatures below 5°C encountered along the delivery route.

Troken Floor PUR WB-C is a two-component, water-based, colored coating with a satin finish based on polyurethane resin. It is characterized by full UV resistance and bacteriostatic properties. It is designed to create a topcoat in the Troken Floor PUR SL 60 .

Troken Floor PUR SL 60 is an aromatic, odorless, two-component, flexible polyurethane coating designed for industrial and decorative floors in residential and public buildings. This self-leveling product has self-venting properties. The coating is highly mechanically and chemically resistant, and available in a variety of colors.

Epoxy resin for floor screeds. Self-leveling and solvent-free, resistant to chemicals (alkalis, diluted acids, gasoline, oils, and many solvents), it is available in a wide range of RAL colors. It has a Greek hygiene certificate and is certified for contact with food and alcohol, making it suitable for use in food production and processing areas.

A two-component, solvent-based flooring resin ideal for industrial applications. It creates highly mechanically and chemically resistant coatings. It is easy to clean and repels dirt.

Polyurethane resin is resistant to UV radiation and other atmospheric factors. It provides high mechanical and chemical resistance.

It provides very high chemical and mechanical resistance. The resin can be applied in thick layers – up to 190 microns in a single layer.

- NOTE: THIS IS A WATER-BASED PRODUCT. Select temperature-controlled shipping to receive your product on the promised date, regardless of weather conditions. Standard shipping may be delayed due to temperatures below 5°C encountered along the delivery route.

An epoxy coating for floors and walls, as well as for covering mineral substrates or repainting tiles. Suitable for use in food processing plants.

A polyaspartic/polyurea flooring resin that allows for application of the entire system within 8 hours. It provides a coating with high mechanical resistance. It cures at lower temperatures, even down to -10°C .

Solvent-free, high-build polyurea/polyaspartic resin. Complete system (primer + two resin coats) in 9 hours (at 25°C). Can also be applied at low temperatures, down to -10°C .

A polyaspartic resin that provides waterproofing and aesthetics on terraces and balconies. Resistant to weather conditions and UV radiation.

- NOTE: THIS IS A WATER-BASED PRODUCT. Select temperature-controlled shipping to receive your product on the promised date, regardless of weather conditions. Standard shipping may be delayed due to temperatures below 5°C encountered along the delivery route.

- Product

- Closing layer

A two-component, water-based aliphatic resin. Creates a hard, abrasion-resistant surface.

- NOTE: THIS IS A WATER-BASED PRODUCT. Select temperature-controlled shipping to receive your product on the promised date, regardless of weather conditions. Standard shipping may be delayed due to temperatures below 5°C encountered along the delivery route.

A varnish for protecting resin, concrete, microcement, and brick floors. UV-resistant – non-yellowing. Available in three finishes: Matte, Satin, and Gloss.

Polyurethane varnish for walls and floors. Protects concrete, brick, and resins. Available in two finishes: glossy and semi-matte. UV-resistant.

Troken Floor FAST Special is a high-build, fast-curing, self-leveling epoxy resin designed for industrial applications and decorative projects requiring a perfectly smooth surface. The product allows for the application of 1 to 15 mm of resin in a single layer. It is characterized by very low volatile organic compound (VOC) emissions, making it virtually odorless.

TrokenPox Accelerator is a specialized primer additive designed to accelerate the curing process of epoxy resins. It shortens epoxy curing time by up to 6 hours, even at low temperatures.

A two-component, solvent-free epoxy primer for dry and oiled concrete substrates. It strengthens the substrate, creates a bonding layer, and adheres perfectly to concrete surfaces.

A single-component polyurethane primer designed for surface preparation before applying resin systems. Ideal for asphalt , cement , and metal . Quick-drying and flexible , it provides excellent adhesion and shortens project implementation time.

Does the resin on the floor scratch?

keyboard_arrow_down keyboard_arrow_upResin floors are highly scratch-resistant. However, like any floor, resin floors can be scratched, especially in heavily used areas. It's recommended to use pads under furniture and avoid sliding heavy objects directly across the floor. For additional protection, a resin-based varnish can strengthen the floor against scratches.

How to prevent resin cracking?

keyboard_arrow_down keyboard_arrow_upTo prevent cracking, carefully prepare the substrate, avoid excessive loads, and follow the manufacturer's application recommendations. If there are expansion joints in the concrete substrate, they should be reconstructed to allow the concrete to move freely and prevent excessive stress on the resin floors.

Is a resin floor slippery?

keyboard_arrow_down keyboard_arrow_upResin floors can be slippery, especially with a high-gloss finish. In such cases, it's worth using anti-slip coatings. Anti-slip properties can be achieved by adding special microbeads or filling them with quartz sand.

Can tiles be laid on resin?

keyboard_arrow_down keyboard_arrow_upYes, you can lay tiles on a resin floor, provided it's properly prepared. The surface of a resin floor is smooth, so tile adhesive won't have the necessary adhesion to work with the resin. Therefore, it's necessary to, for example, cover the wet resin with sand or perform other work later to increase the adhesion of the tile adhesive.

Is floor resin suitable for underfloor heating?

keyboard_arrow_down keyboard_arrow_upYes, resin works perfectly with underfloor heating, ensuring even heat distribution. However, it's important to remember that underfloor heating can only be used after the coating has fully cured, which for many resins can take up to 7 days.

Proven products

We offer products with high durability and technical parameters, ensuring long-lasting results.

Help in choosing

Wondering which products will best suit your needs? Call us – we'll advise you and choose the right solution.

Contractor support

Need help with construction work? Let us know, and we'll recommend trusted contractors.

Stationary points

Want to pick up your products in person? Or perhaps you'd prefer to chat face-to-face? Visit our branches in Warsaw, Wrocław, Katowice, or Gdańsk.