TrokenTech flooring systems

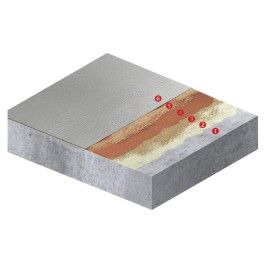

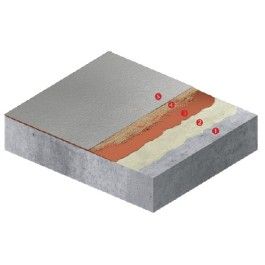

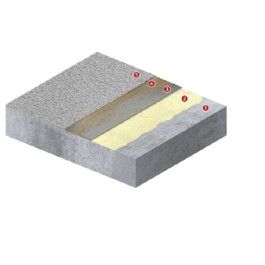

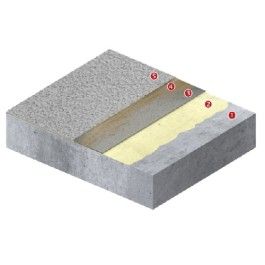

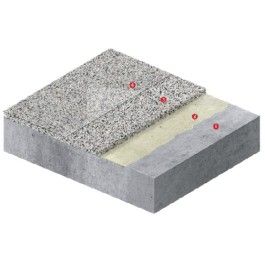

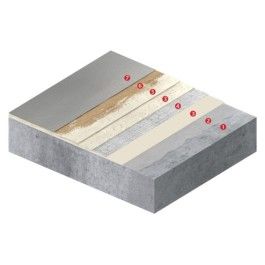

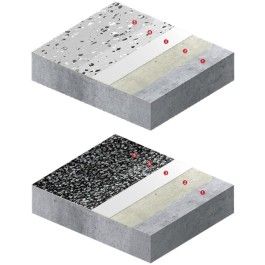

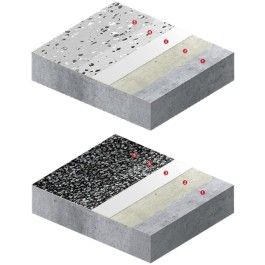

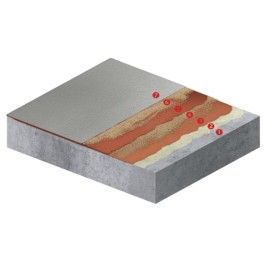

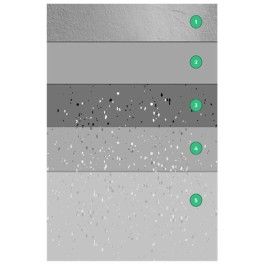

TrokenTech's portfolio of flooring systems based on various resins includes all the latest solutions available on the market. These allow for a floor tailored to the client's specific investment needs. Each layer of the system is a highly specialized solution that creates a cohesive whole. Neopox® Primer WS , designed for damp concrete, is the ideal primer for Polish weather conditions and typical outdoor applications. For dry substrates requiring reinforcement, such as screeds or anhydrite, Epoxol® Primer . This solvent-based primer penetrates deep into the concrete pores, saturating it and simultaneously strengthening it to ensure the floor acquires all the necessary parameters for the application of subsequent resin-based layers. Another primer also used in the system solutions offered is Epoxol® Primer SF-P . This product has several different applications, from priming and sealing substrate absorbency to building repair compounds or even epoxy screeds when mixed with various fractions of quartz sand. In TrokenTech resin flooring systems, this product is used in various variants, depending on the complexity and intended use.

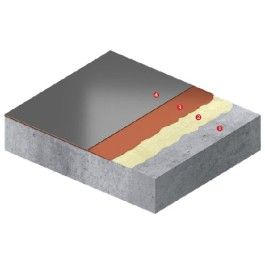

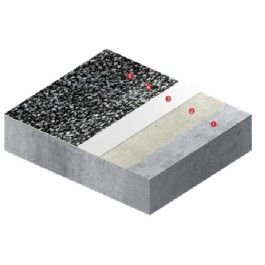

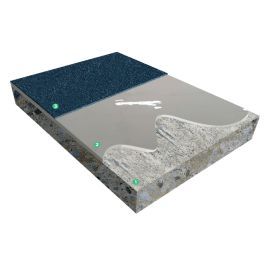

The intermediate layers in the proposed systems are based on, among other things, the aforementioned Epoxol® Primer SF-P mixed with quartz sand, which in this variant allows for the construction of the appropriate floor thickness. Another product also used for this purpose is Epoxol® Floor . This self-leveling epoxy resin allows for application up to 3 mm thick in a single layer. Furthermore, it can be mixed with quartz sand at a 1:1 ratio, which not only translates into material savings and a lower price per square meter of resin flooring, but the quartz sand that settles to the bottom further enhances adhesion to the preceding layer.

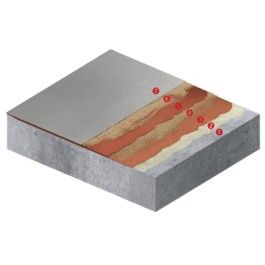

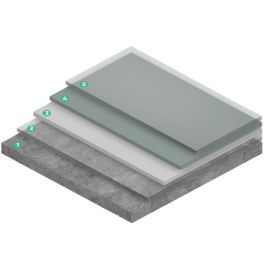

Neodur® Special or Neopox® Special are used as the intermediate layer . These are polyurethane and epoxy resins, respectively, which are solvent-based. Both offer excellent mechanical and chemical resistance, meaning they are resistant to many chemicals. Another thin-film product used as an intermediate layer is Neopox® W Plus . This resin, in turn, is a water-based epoxy, making its application more environmentally friendly, as it contains fewer volatile organic compounds (VOCs) than solvent-based products. This, in turn, reduces unpleasant odors during application. Intermediate layers also include fast-drying products based on polyaspartic resin. Their rapid curing allows some systems to be completed in a single day and ready for use after just 24 hours. Products that build fast-drying systems are included in the Neodur® Fast Track , which is also available in a solvent-free version with reduced unpleasant odor and is designated SF for "Solvent Free."

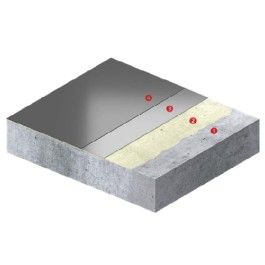

Topcoats in the TrokenTech flooring system portfolio are most often a combination of the previously mentioned products, depending on the complexity, thickness, location, and color of the final coating. Products from the resin coating lines, such as Neodur® Special and Neopox® W Plus, allow for the production of almost all RAL colors. Additionally, the self-leveling epoxy Epoxol® Floor is also tintable, similarly to the aforementioned resins. It's worth noting that both Neodur® Special and the entire Neodur® Fast Track are fully resistant to UV rays and weather conditions, making them suitable for outdoor use. Therefore, the complete versatility of the systems allows for the selection of the appropriate solution depending on the customer's needs and specific investment requirements, such as mechanical resistance, chemical resistance, slip resistance class, or color of the final coating.

What are flooring systems?

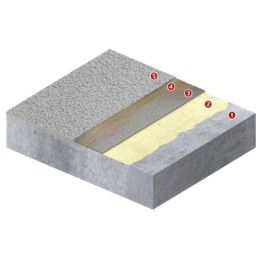

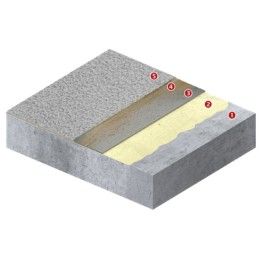

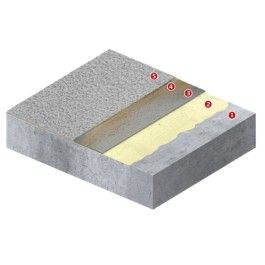

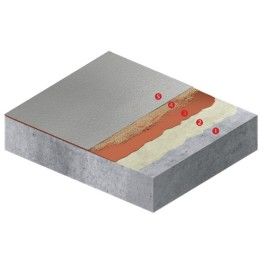

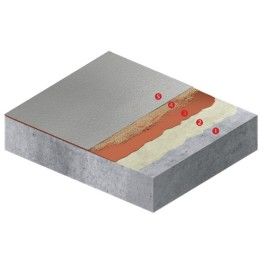

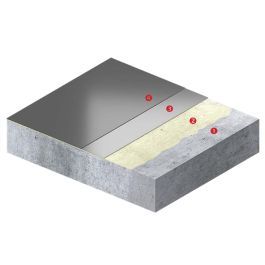

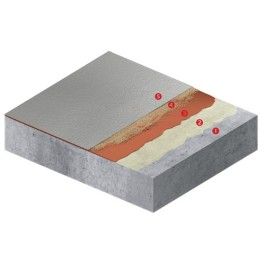

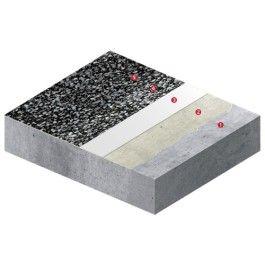

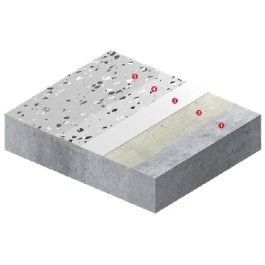

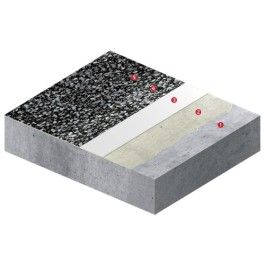

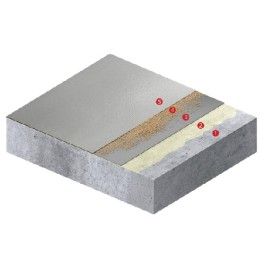

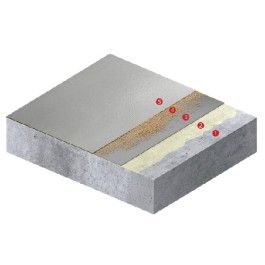

Flooring systems are solutions that encompass a range of materials and flooring technology, tailored to specific technical, functional, and aesthetic requirements. These solutions are called systems because they incorporate a comprehensive approach, encompassing several carefully selected layers, such as an intermediate layer or a topcoat.

Most system solutions based on resin-based products consist of tailored primers, such as epoxy primers, for specialized applications. One such primer is Neopox® Primer AY , a capillary-rising primer used on concrete substrates that have not been insulated from groundwater, among other things. Another primer included in the systems is Epoxol Primer®, a primer for screeds and anhydrites. These are highly absorbent concrete substrates. The system also offers primers for use on damp outdoor concrete, such as Neopox® Primer WS .

After properly priming the substrate, subsequent layers of the proposed system solutions include intermediate layers based on solvent-free epoxy resins such as Epoxol® Floor and Epoxol®Primer SF-P, which allow the applied system to achieve most of its target thickness. The use of epoxy-based solutions allows the floors to be used under heavy mechanical loads, including heavy traffic, forklifts, and heavy industrial machinery. Furthermore, the high chemical resistance of epoxy resins, as well as polyurethane and polyaspartic resins, expands the range of flooring applications to include garages, laboratories, the chemical industry, and the food industry.

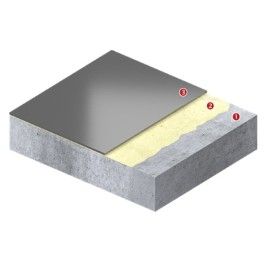

Topcoats, the final element of flooring systems, are most often coatings made of polyurethane resin, but also epoxy or polyaspartic resin. The latter two groups of resins are fully resistant to UV and weather conditions, making them suitable for both indoor and outdoor use. The use of quartz sand in the preceding layer or the final layer of an anti-slip additive in the form of microbeads ( Neotex® Antiskid M ) allows for achieving the appropriate floor roughness class, which is particularly important when using the system outdoors. Smooth coating finishes are also available, providing a completely even, uniform surface. These solutions are suitable for areas where humidity is low or a specific aesthetic is required. Furthermore, the top layers of the proposed systems include products available in a variety of colors, including those that can be tinted upon request. This translates into a wide range of resin floor finishing options that combine safety and appropriate floor protection with aesthetic appeal.

Flooring systems - tailored to various needs

Our flooring systems offer a wide range of solutions, suitable for industrial facilities, public spaces, and residential properties. Each project has its own unique parameters, such as the load the resin floor will be subjected to, as well as the color and finish. Therefore, TrokenTech's flooring systems have been divided into categories, which, using appropriate filters, will reveal the best-suited solutions for the specific requirements of the flooring project.

Industry

Industrial flooring systems must meet the highest standards of mechanical strength and resistance to chemicals, impacts, and intensive use. TrokenTech offers resin industrial flooring that combines durability with functionality.

Warehouses and logistics centers

In warehouse spaces, load resistance and ease of cleaning are crucial. Flooring systems from the TrokenTech portfolio meet these requirements, ensuring long-term use without the need for frequent renovations. Seamless coatings are easy to keep clean, requiring only warm water, a mild detergent, and a soft mop.

Commercial and office buildings

Aesthetics and functionality are key aspects in commercial and office buildings. Resin floors are available in a variety of patterns and colors, allowing them to be matched to interior design. A wide range of solutions, from smooth, uniform surfaces to non-slip finishes and decorative flakes, create a comprehensive portfolio of flooring systems.

Medical and pharmaceutical facilities

Hygiene, resistance to disinfectants, and seamless construction are key features in medical facilities. TrokenTech's flooring systems meet stringent hygiene standards, ensuring a safe working environment. Smooth resin floors minimize dirt retention, which can harbor various pathogens.

Sports facilities

Abrasion resistance and anti-slip properties are essential in sports facilities. Resin flooring systems are ideal for sports halls and gyms.

Apartments and houses

Our flooring systems offer modern solutions for residential interiors, combining functionality with elegance. Mirror effects and the addition of decorative flakes translate into a unique visual effect while maintaining the highest levels of mechanical, chemical, and abrasion resistance.

Types of resin flooring systems

Epoxy floors

They are characterized by high mechanical and chemical resistance. They are ideal for industrial and residential applications. Thanks to a wide range of flooring systems based on solvent-based, water-based, and solvent-free products, it is possible to work in various spaces without having to shut down the entire apartment or industrial hall.

Polyurethane floors

These are fast-acting flooring systems, offering the ability to create a resin floor in as little as 24 hours. Furthermore, the products included in these systems can be applied at low temperatures, even around 0°C, which is simply impossible with polyurethanes and epoxies.

Decorative floors

They provide a unique look, combining aesthetics with functionality. Ideal for both residential and commercial interiors. Using decorative flakes in this type of flooring system not only enhances the aesthetics of the project but also visually conceals minor imperfections.

Anti-slip floors

Designed to ensure safety in areas with a high risk of slipping, such as sports facilities, manufacturing plants, and anywhere with high humidity. Various anti-slip classes, ranging from R9 to R13, allow for the adjustment of the surface roughness depending on the slipping risk.

How to choose the right flooring system?

The choice of flooring system depends on the intended use, the expected load, and hygiene and aesthetic requirements. It's crucial to consider the specific characteristics of the space, such as weather conditions, including exposure to UV rays, chemical exposure, and traffic intensity. TrokenTech offers expert advice, helping to select a solution perfectly suited to the client's needs.

Why choose flooring systems?

- Durability and strength: Flooring systems from the TrokenTech portfolio are highly resistant to abrasion, chemicals and mechanical loads.

- Versatile use: Suitable for a variety of spaces, from industrial to residential. Thanks to its parameters, it is suitable for use by heavy equipment such as forklifts, and, after appropriate varnishing, for animals such as dogs.

- Aesthetics: Available in a wide range of colors and patterns. The option of tinting selected solutions according to the RAL palette or using decorative flakes allows for almost complete customization of the floor design based on the flooring system.

- Safety: Anti-slip options and seamless construction minimize the risk of accidents. Several anti-slip classes, up to R13, allow you to tailor the roughness of the flooring system's topcoat to your individual needs.

- Hygiene: Thanks to the seamless nature of the flooring systems, keeping your floor clean is easy. All you need is warm water, a mild detergent, and a soft-bristled mop.

The process of applying flooring systems

Flooring systems consist of several layers, requiring several application stages to create a fully functional floor based on the chosen resin. The most common stages of resin flooring systems are explained below:

Preparation of the substrate

Removing existing coatings, cleaning the surface, and leveling it are key preparatory steps. Uneven surfaces can lead to an unsatisfactory visual result, while leaving any dirt behind will significantly affect the adhesion of the entire system to the floor.

Applying the primer

Applying primer improves the adhesion of the flooring system to the substrate. This step is also crucial, as is preparing the substrate. A properly primed floor will have a full gloss. If dull spots appear, an additional layer of primer should be applied. An improperly primed substrate will significantly reduce the adhesion of the entire resin flooring system.

Base layer application

The base layer provides the floor with structure and mechanical strength. Therefore, it is often referred to as the carrier layer, as it provides the mechanical strength of the entire system.

Application of the finishing layer

It is responsible for the aesthetics and functionality of the floor, such as its anti-slip properties or decorative appearance. It is the final step in applying resin products in flooring systems. It often contains colored resins or clear varnishes if a decorative effect, such as decorative flakes, was applied in the previous layer.

Hardening

The curing process ensures durability and resistance to wear and tear. This is the stage during which the flooring acquires all its mechanical and chemical properties. Full curing time varies and depends on the type of resin used to create the flooring system. Epoxies and polyurethanes typically cure within 7 days of applying the final coat, while polyureas can take up to 24 hours.

How to care for flooring systems?

To ensure the longevity of your flooring system, it is worth following a few simple rules:

- Regular washing using dedicated cleaning products.

- Avoiding aggressive chemicals unless the system is resistant to them.

- Periodic inspection of the floor condition and repair of minor damage.

- Surface protection against excessive loads and impacts.

Trokentech flooring systems guarantee quality, durability and aesthetics, tailored to the needs of each customer.

TrokenTech's flooring systems offer comprehensive solutions designed for various loads, intended use, and coating finish. Thanks to this detailed approach, each flooring system consists of primers and other necessary layers that provide the floor with the appropriate durability and finishing effect. Carefully selected primers guarantee the highest quality floor protection, while a wide range of systems allows for customization to specific site requirements. The availability of various finishes, from smooth surfaces to non-slip options, expands the range of applications for systems based on epoxy, polyurethane, or polyaspartic resin coatings. The concept of our systems is to maximize the ability to personalize the solution to specific project requirements. Therefore, many resin flooring systems offer the option of coloring the final coating upon request or adding additives (e.g., flakes or colored sand) to provide a decorative effect.