Epoxol® Floor C-15r SF-P - flooring system

Anti-slip, solvent-free epoxy coating system for indoor industrial floors.

The Epoxol® Floor C-15r SF-P system is ideal for:

- food industry

- laboratories

- medical care centers

Key features:

- dry layer thickness: ~1.5 mm

- for medium-duty floors

- solvent-free - low odor

- anti-slip finish

- LEED compliant for VOC emissions and VOC content

- suitable for use in the food industry

|

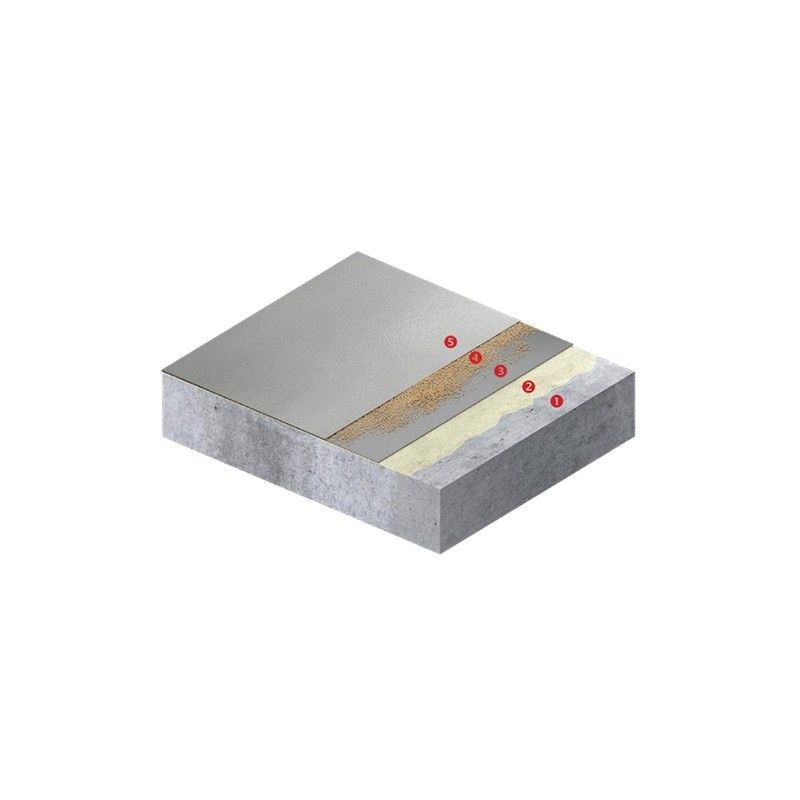

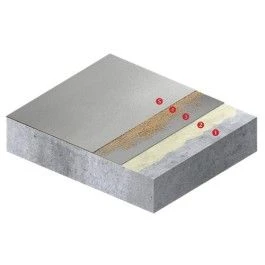

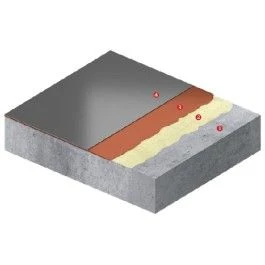

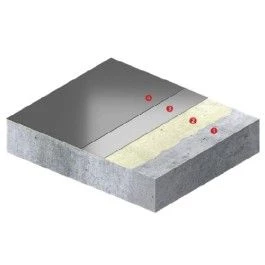

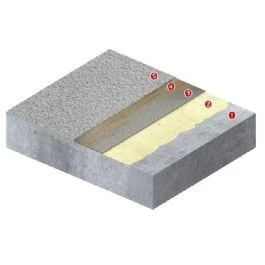

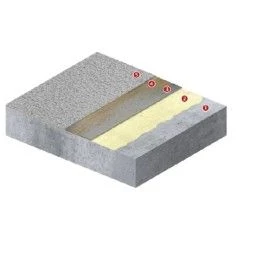

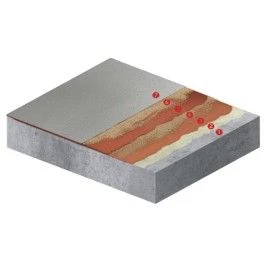

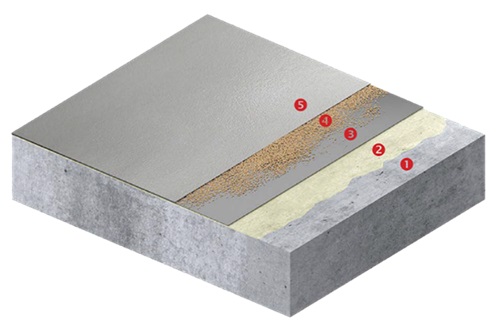

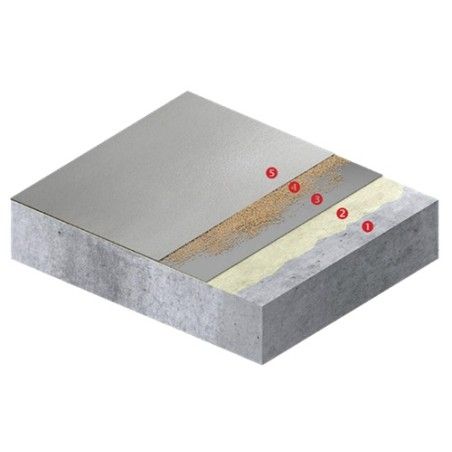

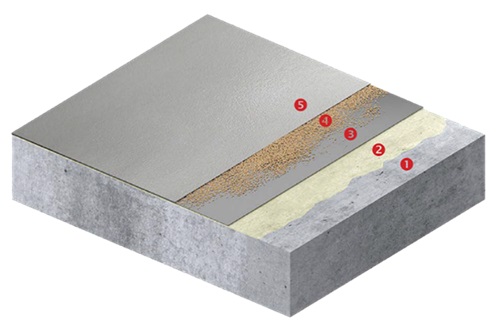

Construction of the Epoxol® Floor C-15r SF-P system and approximate consumption

|

|

Layer

|

Product

|

Wear

|

|

Priming*

|

Epoxol® Primer SF-P

|

200-300 g/![]() m2 in one layer m2 in one layer

|

|

Base layer

|

Epoxol® Floor

|

~300 g/![]() m2 in one layer m2 in one layer

|

|

Cover with quartz sand

|

Quartz sand 0.3-0.8 mm

|

~3 kg/![]() m2 (in excess ) m2 (in excess )

|

|

Sealing layer

|

Epoxol® Floor

|

~500 g/![]() m2 in 1-2 layers m2 in 1-2 layers

|

*An alternative primer from Neotex can be used after consultation with our Technical Advisor.

Epoxol® Primer SF-P – a two-component, solvent-free epoxy resin. This product can be used both for priming concrete (and other mineral substrates) and for combining with quartz aggregate to create repair compounds or epoxy screeds.

Epoxol® Floor – a two-component, solvent-free, self-leveling epoxy resin. It creates an aesthetically pleasing finish while protecting the floor from mechanical and chemical factors. The floor becomes easily cleanable and smooth. It is certified for food contact, making it suitable for use in food production and processing facilities, restaurants, breweries, and more.

Quartz sand – an additive to resins that imparts anti-slip properties to surfaces. Often used as an additive to increase their strength and hardness. Available in various sizes.

.jpg)

.png)

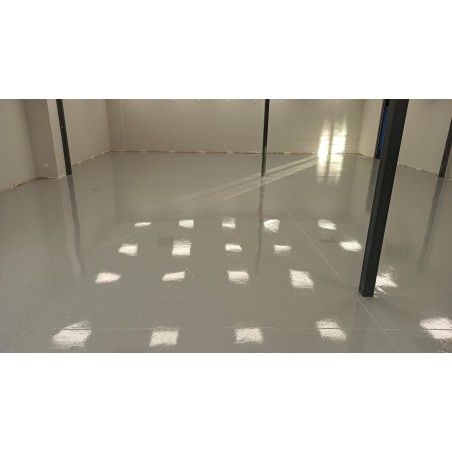

Floors made in the Epoxol® Floor SF-P system:

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)