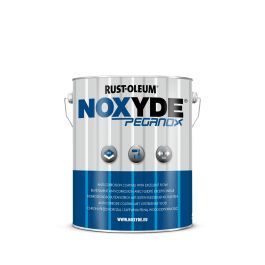

Polyurethane aluminum anti-corrosion paint for steel, metal, or concrete. Can be applied at low temperatures (-18°C) and high humidity (up to 99%)— practically year-round, regardless of weather conditions. For anti-corrosion protection and painting of bridges, steel structures, roofs, steel pipes, etc.

- Wroclaw,

- Katowice,

- Warsaw,

- Gdansk,

- +48 717 026 346

Anti-corrosion paints for C4 and C5

To effectively protect surfaces from rust and its destructive effects, it's important to use specialized products optimized for the specific conditions and corrosiveness class of the environment they will be used in. This category includes C4 and C5 anti-corrosion paints – suitable for spray application as well as traditional application methods using painting accessories. Most of our products can be ordered in any color, choosing from a wide range of RAL shades.

Where to use C4 anti-corrosion protection?

We offer anti-corrosion paints with a corrosion class of C4. They are used on outdoor steel structures in environments characterized by significant air pollution. Choose these products if the risk of corrosion is primarily related to:

- proximity to the sea, which causes atmospheric precipitation to contain a large amount of salt that negatively affects metal surfaces,

- high air humidity,

- air dust resulting from the presence of industrial facilities emitting harmful dust,

- the content of sulfur oxide in the air – it is the cause of so-called acid rain, which has a particularly negative effect on elements made of carbon steel, nickel, zinc, and copper,

- frequent changes in temperature and sunlight – moisture combined with extreme weather conditions favors the development of rust.

Corrosion class C4 applies primarily to coastal and industrial areas, but also to swimming pool hall structures.

C5 anti-corrosion protection – application

In chemically aggressive environments, high-performance metal surface protection is essential – for this purpose, C5 anti-corrosion paint . A C5 corrosion class means that steel structures are susceptible to airborne gases such as sulfur dioxide, hydrogen chloride, hydrogen sulfide, ammonia, as well as sulfuric acid vapors and high inorganic salt content.

C4 and C5 anti-corrosion paints – check available preparations

We offer direct-to-rust elastomers that can be applied without sanding or prior surface preparation. They create a waterproof coating with anti-corrosion properties. They are suitable for steel structures located in highly aggressive environments. We also offer polyurethane paints for metal . They also work well on wood, concrete, and steel. Use them if you want to protect the painted surface from atmospheric factors and chemicals. They create a smooth, scratch-resistant layer. High adhesion and efficiency are the key advantages of our solutions.

If you want to protect metal surfaces – including galvanized ones – against the destructive effects of gases and acids, choose epoxy metal paints .

Choose anti-corrosion paints for demanding areas in the C4 and C5 classes

Drawing on years of experience, we've compiled the best anti-corrosion paints for aggressive and industrial environments. When planning to paint surfaces with a C5 corrosion class, the coating thickness must be precisely selected – only then can you guarantee effective rust protection. Our consultants will be happy to help you purchase the right products, providing substantive support and verifying the specific requirements of each client.

Product offer

Water-based anti-corrosion coating for application by roller or brush. No priming required.

Epoxy primer for steel. Protects against corrosion and has high chemical resistance.

Industrial epoxy primer. Protects against corrosion and has excellent adhesion to metals and galvanized substrates.

High-gloss epoxy enamel. For use as a topcoat in interior anti-corrosion systems. Highly mechanically and chemically resistant.

High-gloss industrial polyurethane enamel. Suitable for spray application. Highly chemically and mechanically resistant.

Industrial enamel for use as a topcoat in anti-corrosion systems. It dries quickly and is highly resistant to chemicals and weather conditions.

An epoxy resin primer for industrial applications. Quick-drying and high-build, it provides anti-corrosion protection for metal surfaces.

A primer for epoxy, acrylic, and polyurethane topcoats. Durable in changing weather conditions, continuous contact with water, and industrial environments. Provides anti-corrosion protection and excellent adhesion.

A highly decorative primer for the protective and decorative painting of metal surfaces. Highly opaque, hard, and scratch-resistant.

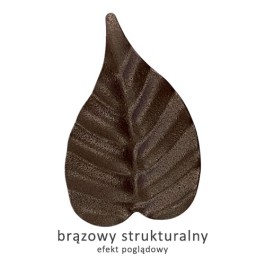

A decorative primer with a fine-grained texture. Designed for protective and decorative painting of metal surfaces without prior priming.

Anti-corrosion enamel for use on steel and cast iron structures, non-ferrous metals as well as concrete, wooden and plastered surfaces to protect against the harmful effects of atmospheric factors.

A primer that protects surfaces from rust in corrosivity classes C3 to CX. Can be applied even over rust residue. Contains aluminum pigments.

A quick-drying industrial primer/enamel. Available in a variety of colors, it requires no priming and contains anti-corrosive pigments.

Anti-corrosion paint for C4 and C5 - what does it mean?

keyboard_arrow_down keyboard_arrow_upThe designations "C4" and "C5" denote environmental corrosivity classes, found in the PN EN ISO 12944-2 standard. Classes C4 and C5 denote high and very high (industrial) classes, respectively. The paint system should be selected according to the corrosiveness of the environment and the required coating durability. Anti-corrosion paints used in these cases are two-component products. Chemically resistant – epoxy and polyurethane coatings. The exception is the single-component high-build elastomer Noxyde , which can be used up to class C5.

How long does it take to dry?

keyboard_arrow_down keyboard_arrow_upTwo-component products—epoxies and polyurethanes—dominate in anti-corrosion systems for classes C4 and C5. These are chemically cured paints that typically require 24 hours to recoat.

C4 anti-corrosion protection - what to choose?

keyboard_arrow_down keyboard_arrow_upFor C4 corrosion class, you can opt for the single-component Noxyde , which can be applied over rust, making the substrate preparation process less expensive. If the project specifications require the use of an epoxy-polyurethane system, in this case, we can choose, for example: - Telpox P 100 - layer thickness 80μm + Telpur T 300 - layer thickness 40μm - the total coating thickness will be 120μm, and the durability in this case is at least 7 years - Telpox P 100 - layer thickness 100μm + Telpur T 300 - layer thickness 80μm - the total coating thickness will be 180μm, and the durability in this case is from 7 to 15 years

Corrosion class C5 - what coating thickness?

keyboard_arrow_down keyboard_arrow_upCorrosion class C5 indicates an aggressive industrial environment with high humidity and air pollution. In this case, we can choose: - Noxyde , which in two layers provides a coating thickness of 300-350μm dry and ensures a durability of at least 10 years; - an epoxy-polyurethane system, where, depending on the required durability, the coating thickness should be 240 to 300μm.

Proven products

We offer products with high durability and technical parameters, ensuring long-lasting results.

Help in choosing

Wondering which products will best suit your needs? Call us – we'll advise you and choose the right solution.

Contractor support

Need help with construction work? Let us know, and we'll recommend trusted contractors.

Stationary points

Want to pick up your products in person? Or perhaps you'd prefer to chat face-to-face? Visit our branches in Warsaw, Wrocław, Katowice, or Gdańsk.