One-component primer enamel protecting against rust in environments with corrosivity class up to C3. Many color versions.

- Wroclaw,

- Katowice,

- Warsaw,

- Gdańsk,

- Poznań

- +48 717 026 346

Anti -corrosive paints

What are anti -corrosion paints?

Anti -corrosion paints are specialized protective coatings that prevent rust on metal surfaces. They are used in various industries, from heavy industry to home use, where metal constructions are exposed to moisture, salt or chemicals.

How do anti -corrosion paints work?

Anti -corrosion paints work by creating a protective barrier between metal and external factors such as oxygen, moisture and chemical pollution. Depending on the composition, they can:

- insulate the metal surface from corrosion factors,

- contain corrosion inhibitors that chemically counteract the rust process, e.g. zinc phosphate,

- Act as a conductive layer that prevents corrosive cells.

The use of anti -corrosive paints

Anti -corrosion paints are widely used in:

- construction - protection of steel elements of bridges, halls and supporting structures,

- automotive industry - protection of bodies and chassis of vehicles,

- maritime industry - protection of ships and drilling platforms against sea water,

- households - protection of fences, balustrades and other metal elements exposed to weather conditions.

Types of anti -corrosive paints

Alkyd paints

These are one of the most commonly used anti -corrosive paints. They are characterized by good adhesion to the ground and resistance to weather conditions, e.g. telryd S200 , i.e. primer alkyd dyed in accordance with the RAL palette .

Epoxy paints

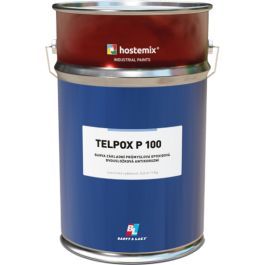

Paints with very high chemical and mechanical resistance. Used mainly in industry and on surfaces requiring long -term protection. Neopox® Primer 815 or Telpox P100 is often used . They provide excellent anti -corrosion protection of the substrate, and also create adequate grip conditions for subsequent layers of systems.

Polyurethane paints

They provide permanent protection and aesthetic finish. Often used as a top surface in protective systems, although they can also be used as undercoat paints as well as primers. An example of a polyurethane anti -corrosion foundation is Krypton Proline PU al Primer Krypton Proline Silver TC Krypton Paints , and Gruntoemalia Telpur S210 .

Zinc paints

They contain zinc particles that act as an anode, preventing corrosion at the electrochemical level. Used mainly in heavy industry and steel structures. Cold galvanists in the form of paint or spray are often found, e.g. Galva Zinc or Galva Zinc Spray .

How to prepare metal for painting with anti -corrosive paint?

Surface purification

Before painting, thoroughly clean the metal of rust, dust and fat. This can be done mechanically (grinding, sandblasting) or chemically (degreasing preparations and rust -right).

Rust removal

If there is rust on the metal surface, it should be removed with a wire brush, sandpaper or a special chemical. You can also use rust converters that transform visible rust into a less reactive form. Top-kor is used for this-only for solvent products and Neodur® Metal Force for both water and solvent products.

Degreasing

The metal must be degreased so that the paint adheres well. For this purpose, you can use solvents or dedicated preparations such as Sulfanol A or Emulsol .

Application of anti -corrosion foundation

For additional protection, it is worth applying a special anti -corrosive foundation that increases the paint's grip and strengthens its protective effect. Epoxy anti -corrosion soils such as Neopox® Primer 815 .

How to apply anti -corrosion paints?

Anti -corrosion paints can be applied in several ways:

- Brush - a method ideal for painting small surfaces and details,

- Roller - quick covering of large surfaces,

- Spraying - a professional method, providing an even coating without streaks.

Before painting, mix the paint thoroughly and follow the manufacturer's recommendations regarding temperature and application conditions.

Product offer

Epoxy primer for steel. It protects against corrosion and has high chemical resistance.

Primer for epoxy, acrylic and polyurethane topcoats. Durable in changing weather conditions, constant contact with water and industrial atmosphere. Provides anti-corrosion protection and excellent adhesion.

Fast-drying industrial primer enamel. Available in many colors, does not require priming and contains anti-corrosion pigments.

Polyurethane anti-corrosion aluminum paint for steel, metal or concrete. Can be applied at low temperatures (-18°C) and high humidity (up to 99%) - practically at any time of the year, regardless of weather conditions. For anti-corrosion protection and painting of bridges, steel structures, roofs, steel pipes, etc.

A primer that protects surfaces against rust in corrosion class C3 to CX. Possibility of application even on rust residues. Contains aluminum pigments.

Cold galvanizing product, quick-drying. For use on new or cleaned steel surfaces. Product based on polyhydroxyether resin.

Anti-corrosion coating with 90% zinc content in dry film. Provides cathodic protection. For use on new or very well cleaned steel substrates.

Concentrated agent for degreasing surfaces before painting. Mainly recommended for use before painting with anti-corrosion products.

- NOTE: WATER-BASED PRODUCT. Choose temperature-controlled shipping to receive the product on the declared date, regardless of the weather. Standard shipments may be held due to temperatures below 5°C along the delivery route.

- Product

- Substrate preparation

For cleaning concrete, roof tiles and metal before applying paint coatings. Requires rinsing with water.

What anti -corrosion paint is the best?

keyboard_arrow_down keyboard_arrow_upThe choice of the best anti -corrosion paint depends on the operating conditions. Alkyd and polyvinyl paints are often chosen for home use, while zinc, polyurethane or epoxy paints dominate in industry.

How long does anti -corrosive paint work?

keyboard_arrow_down keyboard_arrow_upThe durability of the paint depends on its type and the conditions in which it is used. There are different classes of corrosion environment, as well as various periods of durability, for which the coating thickness and the type of paint are selected. The shortest durability period is up to 7 years and requires the thinnest layers of paint compared to the other periods of the coating strength.

Can anti -corrosive paint be used for rust?

keyboard_arrow_down keyboard_arrow_upSome anti -corrosion paints are adapted to the application directly to rust, but for better durability it is always recommended to clean the surface.

Anti -corrosion paints are an effective way to protect metal against rust. Choosing the right type and proper surface preparation will ensure long -term protection and aesthetic appearance of metal structures.

Proven products

Here you will find products with high strength and technical parameters. Thanks to this, you can enjoy long-lasting effects.

Help in choosing

Are you wondering which products will be best for your needs? Call us - we will advise you and choose the right solution.

Contractor support

Do you need help with construction work? Let us know and we will recommend proven contractors.

Stationary points

Do you want to collect the products in person? Or maybe you prefer to talk live? Visit our branch in: Warsaw, Wrocław, Katowice or Gdańsk.