Polyaspartic resin providing a waterproofing effect and aesthetics on terraces and balconies. Resistant to weather conditions and UV radiation.

- Wroclaw,

- Katowice,

- Warsaw,

- Gdańsk

- +48 717 026 346

Epoxy resin on the floor

Floors made of epoxy resin are becoming more and more popular among people looking for durable and aesthetic solutions for interiors. This modern material is exceptionally durable and attractive in appearance, making it suitable for both homes and commercial and industrial spaces.

What is epoxy resin?

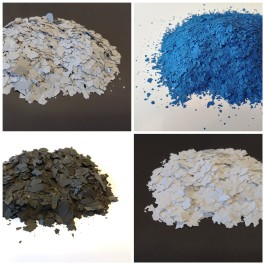

Epoxy resin is a high-strength synthetic polymer material that, when applied, creates a durable and smooth coating. It is used as a modern way of finishing floors, offering both aesthetic and practical values. Epoxy resin is available in various colors. Additionally, you can use many types of decorative finishing, e.g. decorative flakes or liquid granite, which allows you to match it to various interior styles.

Why is it worth using epoxy resin on the floor?

Epoxy resin has many advantages that make it a popular choice among investors choosing a resin floor:

- Durability: It is impact, scratch and abrasion resistant, making it ideal for high traffic areas.

- Chemical resistance: Perfect for places where the floor is exposed to contact with chemicals, e.g. in garages or laboratories.

- Seamless: A uniform surface without joints makes it easier to keep clean and gives the interior a modern look.

- Easy to keep clean: To clean the epoxy floor in good condition, all you need is a soft mop, mild detergent and warm water.

- Possibility of personalization: Thanks to various colors, decorative effects and accessories such as decorative flakes, colored quartz sand or liquid granite, a resin floor can be completely unique and unique.

Types of epoxy resins for floors

Epoxy resin comes in various variants that differ in properties, method of application and use. Here are the most popular types:

Self-leveling epoxy resin:

This type of resin creates a perfectly smooth surface that is both aesthetic and functional. Perfect for residential and commercial spaces. Using this resin, it is possible to obtain the so-called mirror effect, a popular solution used in living rooms and dining rooms in apartments.

Thin-layer epoxy resin

Thin-layer epoxy coatings are more economical and quick to apply. They are used in places with moderate traffic. In the case of such resins, rollers are used, e.g. velvet rollers, to evenly spread the coating on the floor. Epoxy resins applied with a roller leave a thin coating that is several times smaller than in the case of self-leveling resin. To obtain a satisfactory aesthetic effect, it is necessary to focus on the preparation of the substrate to eliminate any defects and unevenness.

Epoxy resin with decorative additives

Adding decorative flakes, metallic pigments or glitter allows you to achieve unique visual effects. This is the perfect solution for modern interiors. It is also worth considering liquid granite, which gives a unique effect by not fully covering the floor. In this particular case, the visual effect depends on the color of the base resin used, as well as the color of the granite itself. The effect obtained this way on the epoxy floor is unique.

Industrial epoxy resin

Epoxy resin is used in warehouses, workshops and garages. It is characterized by the highest resistance to mechanical and chemical damage. Typically, these are the same products used to create self-leveling and thin-layer resin floors, but the difference is in their consumption.

Where can epoxy resin be used on the floor?

Epoxy resin is a versatile material that can be used in various types of rooms:

- At home: in kitchens, bathrooms, living rooms and garages.

- In offices and shops: gives the interior an elegant and modern look. Additionally, protected with resin varnish, the epoxy floor is very resistant to scratches and heavy foot traffic.

- In industrial facilities: due to its durability and resistance to chemicals, it is often used in production halls and warehouses. Also resistant to high mechanical loads, such as passenger cars, trucks and forklifts, epoxy resin works wherever the floor is subjected to high pressure forces.

- In public spaces: schools, hospitals and gyms are places where ease of cleaning and durability are crucial.

- In gastronomy: some epoxy resins have a special certificate that confirms the safety of using a specific resin in places where it will have direct contact with food. Thanks to the conducted research, it is known that the hardened coating created using such a resin is completely safe for food and human health because it does not emit any harmful compounds if used correctly.

Advantages of epoxy resin on the floor

Epoxy resin floors have the following advantages:

- Durability and resistance: they withstand intensive use and are resistant to scratches and damage.

- Hygiene: the seamless surface does not accumulate dust or dirt, which is especially important in medical and catering spaces. Thanks to this, resin floors allow you to create spaces that are safe for people's health.

- Moisture resistance: a floor made of epoxy resin is fully resistant to moisture, so it can be successfully used in bathrooms, kitchens, and also in car washes if someone is looking for an industrial solution.

- Easy to clean: a mop with soft bristles and mild detergents are enough to keep the floor clean. Additionally, warm water will be useful.

- Aesthetics: a wide range of colors and types of finishes allow you to create unique flooring designs.

How to properly apply epoxy resin to the substrate?

The application of epoxy resin requires proper preparation and precision. Here are the steps to follow:

- Surface preparation: Clean the surface of dust, grease and other contaminants. If the floor to be covered with resin is dirty, it should be degreased, e.g. using special agents for degreasing concrete. Then it is necessary to fill in any irregularities and gaps. If the surface is insufficiently prepared, it is more difficult to achieve an aesthetically satisfying final effect. Therefore, this is a key stage to obtain an eye-pleasing epoxy resin floor.

- Priming: Depending on the substrate, a primer is applied to the cleaned, leveled floor surface. In the case of resins, there is a whole range of primers that are also based on resins, most often epoxy, and are suitable for use on tiles, damp, dry or capillary-rising concrete.

- Application of the first layer: A thin layer of epoxy resin is applied with a roller, spreading the material evenly over the entire surface. In the case of self-leveling resins, the material is poured over the floor and spread over the floor using a squeegee, squeegee or trowel with an appropriate tooth.

- Application of subsequent layers: Depending on the expected effect and the thickness of the floor, subsequent layers of both thin-layer and self-pouring products are applied. All necessary information in this regard can be found in technical data sheets or system data sheets provided by the manufacturer of a specific epoxy resin.

- Curing: The resin floor should be allowed to cure completely according to the manufacturer's instructions. It is important to maintain the minimum application temperature, which in the case of most epoxies is around +12°C throughout the floor hardening period, for the process to proceed properly.

How to care for an epoxy resin floor?

An epoxy resin floor is easy to care for, but it is worth following a few rules:

- Regular cleaning: It is worth removing dirt on a regular basis to avoid scratches. Although epoxy resin is highly resistant to scratches, it is of course not indestructible, so it is worth preventing any types of damage.

- Avoiding aggressive cleaning products: Use gentle detergents intended for epoxy resins. The technical data sheet of each product contains information on maintenance, based on which it is worth choosing the appropriate agent for cleaning the resin surface.

- Protection: To protect the resin floor in places where furniture will be placed, it is worth using felt pads. This type of solution also works in traditional flooring systems, such as floor panels. Additionally, it is worth considering that in places exposed to additional factors, such as sand brought into apartments during the winter, the epoxy floor can be protected with resin varnish. This type of solution will not only extend the period of floor renovation, but will also protect it against deep scratches.

Offer of products and systems

Solvent-free epoxy primer intended for use on concrete in the absence or incorrectly performed moisture insulation.

Solvent-based epoxy primer for epoxy paints, polyurethane resins. For use on floors and walls where high mechanical and chemical resistance is required.

Two-component, solvent-based flooring resin, perfect for industrial applications. Creates coatings that are highly resistant mechanically and chemically. It is easy to clean and dirt does not adhere to it.

- NOTE: WATER-BASED PRODUCT. Choose temperature-controlled shipping to receive the product on the declared date, regardless of the weather. Standard shipments may be held due to temperatures below 5°C along the delivery route.

Polyurethane varnish for walls and floors. Protects concrete, brick and resins. Available in two types of finish: glossy and semi-matt. Resistant to UV rays.

Solvent-free, epoxy primer strengthening cement substrates. For internal and external use.

Epoxy resin for use as a primer or construction resin. A solvent-free product for priming walls and floors and creating the so-called epoxy screeds.

Troken Floor EPS is a self-leveling, two-component epoxy screed also used to create a leveling layer, the so-called scratch coat. It is a solvent-free product with low VOC emissions and high mechanical resistance, characterized by a gray color. It is perfect as part of a resin flooring system in apartments, industry and public places.

- NOTE: WATER-BASED PRODUCT. Choose temperature-controlled shipping to receive the product on the declared date, regardless of the weather. Standard shipments may be held due to temperatures below 5°C along the delivery route.

Troken Floor PUR WB-C is a two-component, water-soluble, colorful coating with a satin finish based on polyurethane resin. It is fully resistant to UV. It also has bacteriostatic properties. It is intended to create a surface layer in the Troken Floor PUR SL 60 .

Troken Floor PUR SL 60 is an aromatic, odorless, two-component, flexible polyurethane coating intended for industrial and decorative floors in apartments and public buildings. Self-flowing product with self-venting properties. Highly mechanically and chemically resistant coating, available in many colors.

- NOTE: WATER-BASED PRODUCT. Choose temperature-controlled shipping to receive the product on the declared date, regardless of the weather. Standard shipments may be held due to temperatures below 5°C along the delivery route.

Epoxy coating for use on floors and walls, as well as for covering mineral substrates or repainting tiles. It can be used in food processing plants.

- NOTE: WATER-BASED PRODUCT. Choose temperature-controlled shipping to receive the product on the declared date, regardless of the weather. Standard shipments may be held due to temperatures below 5°C along the delivery route.

Two-component water-based aliphatic resin. Creates a hard and abrasion-resistant surface.

- NOTE: WATER-BASED PRODUCT. Choose temperature-controlled shipping to receive the product on the declared date, regardless of the weather. Standard shipments may be held due to temperatures below 5°C along the delivery route.

Varnish for protecting resin, concrete, microcement and brick floors. Resistant to UV radiation - does not turn yellow. Available in three types of finish: Matt, Satine and Gloss.

Provides very high chemical and mechanical resistance. Possibility of applying the resin in thick layers - up to 190 microns in one layer.

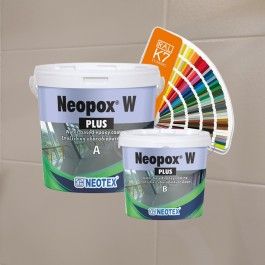

Epoxy resin for floor screeds. Self-leveling and solvent-free, resistant to chemicals (alkalis, diluted acids, gasoline, oils and many solvents), available in many colors from the RAL palette. It has a Greek hygiene certificate and a certificate for contact with food and alcohol - it can be used in places of food production and processing.

Can underfloor heating be used with an epoxy resin floor?

keyboard_arrow_down keyboard_arrow_upYes, epoxy resin works perfectly with underfloor heating systems, ensuring even heat distribution. Underfloor heating can only be used after the epoxy floor has fully hardened.

Can you apply epoxy resin yourself?

keyboard_arrow_down keyboard_arrow_upAlthough the application of the resin requires precision and experience, it is possible to apply it yourself using appropriate tools and following the manufacturer's instructions. You may need a roller holder, a velvet roller, a tray, painting foil, and in the case of self-leveling resins - a squeegee or a squeegee.

Is epoxy resin suitable for any room?

keyboard_arrow_down keyboard_arrow_upYes, epoxy resin is versatile and can be used both in homes and in commercial and industrial spaces. The possibility of using epoxy floors at negative temperatures allows this solution to be used even in cold rooms.

How long does an epoxy resin floor take to dry?

keyboard_arrow_down keyboard_arrow_upThe drying time depends on the ambient conditions and layer thickness, but is usually from 24 to 72 hours. It depends on the type of resin, but also on the conditions during which the floor hardens, such as temperature or air humidity. Full hardening of the coating, i.e. the moment when it acquires all chemical and mechanical resistance parameters, usually takes 7 days from applying the last layer.

Proven products

Here you will find products with high strength and technical parameters. Thanks to this, you can enjoy long-lasting effects.

Help in choosing

Are you wondering which products will be best for your needs? Call us - we will advise you and choose the right solution.

Contractor support

Do you need help with construction work? Let us know and we will recommend proven contractors.

Stationary points

Do you want to collect the products in person? Or maybe you prefer to talk live? Visit our branch in: Warsaw, Wrocław, Katowice or Gdańsk.